A Comprehensive Guide to Temperature Indicator Stickers for Packaging Solutions

The world of packaging is ever-evolving, and as consumer preferences lean toward optimized solutions, the need for specialized indicators has grown exponentially. Among the most invaluable tools in the industry today are Temperature Indicator Stickers. These advanced stickers play a critical role in ensuring product integrity across diverse industries, including food, pharmaceuticals, and industrial goods.

Why Temperature Indicator Stickers Matter in Packaging

Maintaining strict temperature conditions during storage and transit is vital for the integrity of many products. Temperature fluctuations can adversely affect the safety, quality, and usability of items. This is where these stickers step in, providing real-time or historical temperature data to safeguard industries reliant on temperature-sensitive goods.

Whether you’re concerned about protecting perishable items or monitoring industrial equipment, temperature indicator stickers are highly effective and accessible technologies.

How Temperature Indicator Stickers Work

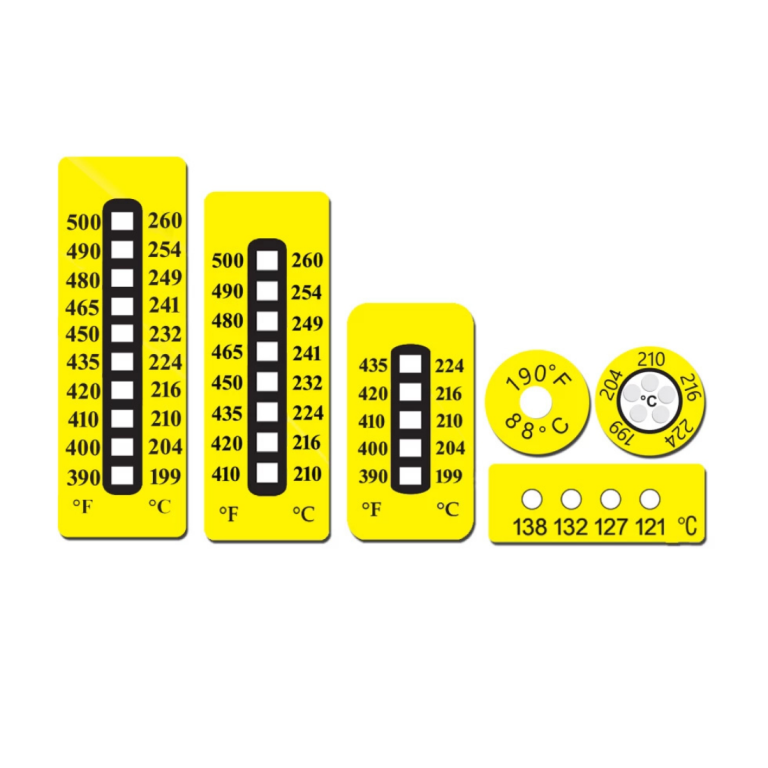

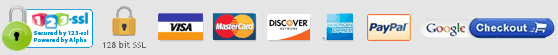

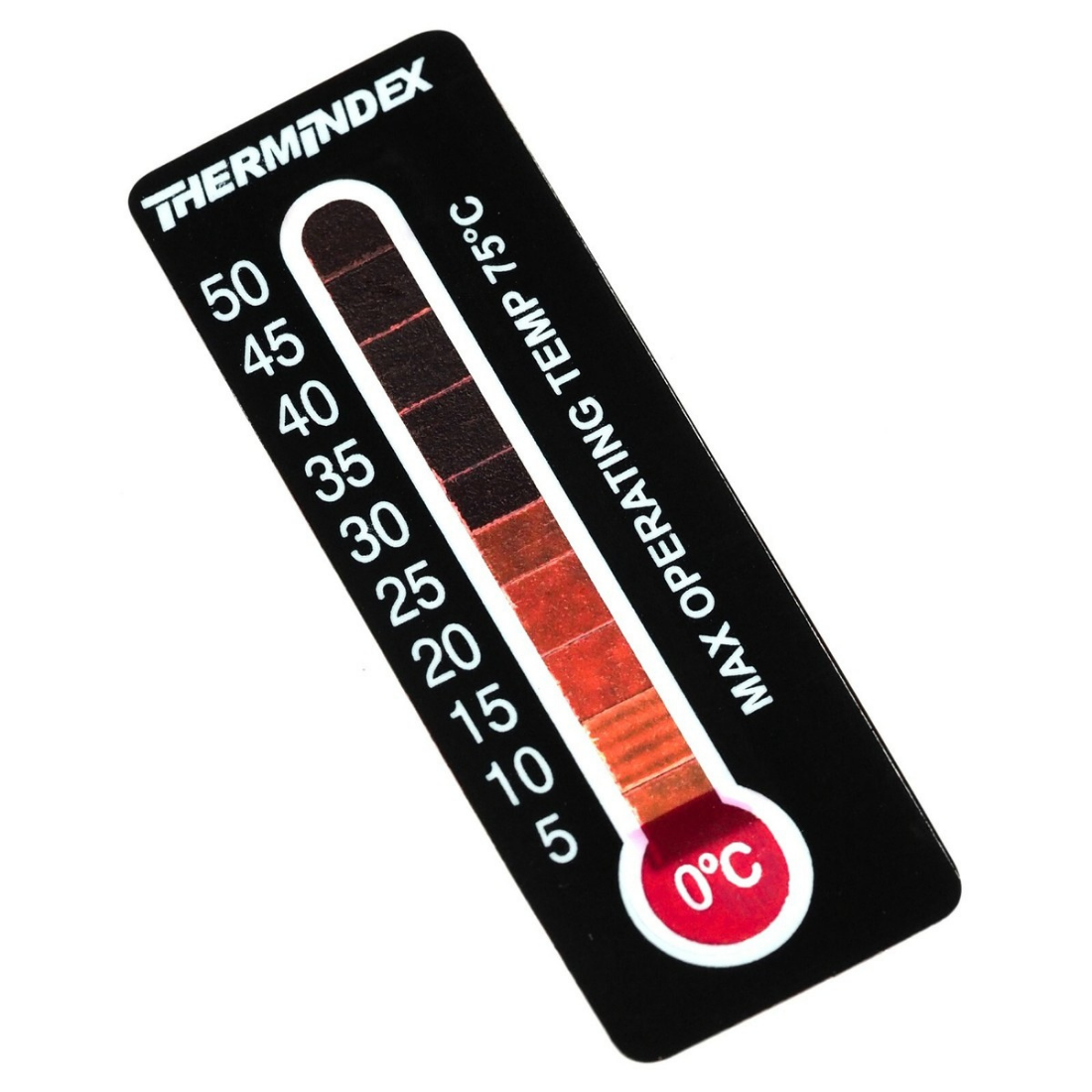

Temperature indicator stickers are engineered to react to specific temperature thresholds. Depending on the type, they may change color, display a numerical value, or provide irreversible marks based on temperature exposure. These labels generally fall into the following categories:

- High Temperature Indicator Stickers: Specifically designed to monitor exposure to elevated temperatures, these solutions are crucial for addressing situations like overheating or fire hazards.

- Irreversible Temperature Indicator Stickers: Ideal for compliance and quality testing, they provide a permanent record once a particular temperature has been exceeded.

- Heat Indicator Stickers: These indicate general heat exposure, offering insights into environmental wear and tear or operational safety levels.

- Temperature Indicator Strips: These versatile strips provide multi-point detection, enabling a broader understanding of temperature variations over time.

The ability to detect threshold breaches in real time can save businesses millions by preventing product spoilage or malfunction.

Applications of Temperature Indicator Stickers in Packaging

From shipping food products to safeguarding expensive machinery, the applications of temperature indicators are diverse and impactful:

| Industry | Application |

|---|---|

| Pharmaceuticals | Ensuring vaccines and other drugs remain within safe temperature limits. |

| Food & Beverage | Monitoring the freshness and safety of perishable goods during shipping. |

| Industrial Manufacturing | Preventing equipment malfunctions by monitoring system temperatures. |

| Logistics & Shipping | Ensuring compliance with shipping standards for temperature-sensitive goods. |

When used as Custom Temperature Indicator Stickers, they can be tailored for unique use cases, further enhancing operational efficiency and precision.

Key Benefits of Using Temperature Indicator Stickers

By adopting temperature indicators, businesses unlock a plethora of benefits, helping them maintain quality, improve traceability, and ensure regulatory compliance. Below are the most notable advantages:

- Enhanced Product Safety: By quickly identifying any temperature excursions, companies can immediately act to preserve product quality and safety.

- Cost Efficiency: Proactive temperature monitoring reduces waste and spoilage, saving resources in the long run.

- Regulatory Compliance: Many industries must adhere to strict regulations regarding the transportation and storage of goods. Using tools like Thermax temperature stickers ensures compliance with ease.

- Customizability: Businesses can work with manufacturers to develop tailored temperature stickers suited to their exact specifications.

How to Choose the Right Temperature Indicator Sticker

Choosing the right indicator requires understanding your operational needs and the specific characteristics of your product or equipment. Factors to consider include:

- Temperature Range: Consider whether you need low, medium, or high-temperature indicators to cover your requirements effectively.

- Irreversible Indicators: Determine whether the application warrants a permanent record of temperature excursions.

- Application Environment: Ensure the sticker material can withstand environmental conditions such as humidity or motion during transit.

- Custom Requirements: If your business has unique needs, you may benefit from partnering with an experienced manufacturer for custom solutions.

Conclusion

Temperature indicator stickers have become a vital component in ensuring the quality, safety, and sustainability of temperature-sensitive goods throughout the supply chain. They provide businesses with actionable data to prevent losses and maintain compliance across various critical industries.

When selecting temperature indicators, partnering with a trusted supplier like Stickers Printing US ensures high-quality, reliable solutions tailored to your exact needs. Optimize your packaging strategy today and gain peace of mind with the latest in temperature monitoring technology.